KACO GmbH + Co. KG

Booth number: 2-C31

kaco.de/en

About us

KACO GmbH + Co. KG, a subsidiary of the Zhongding Group, is one of the world's leading developers and manufacturers of high-precision, application-oriented sealing solutions and electrification components for a wide range of industries. Based in Germany, the company is characterized by the highest sealing quality and innovative strength and stands for recognized development and manufacturing expertise. KACO has six plants in Germany, Austria, Hungary, China and the USA and supplies its products all over the world. As a long-standing partner to the automotive and supplier industry as well as other branches of industry, the company has always kept pace with the high demands and technical changes in the sectors for decades.

Address

Industriestr. 19

74912 Kirchardt

Germany

E-mail: info@kaco.de

Phone: +49 7266 9130-0

Internet: www.kaco.de

Contact person:

Charalambos Gialamatzis

Head of Aftermarket

E-mail: charalambos.gialamatzis@kaco.de

Phone: +49 7266 9130-1379

Products & Services

KACO is a leading provider of high-quality sealing solutions and innovative technologies for the automotive and supply industry. The product portfolio includes customized radial shaft seals, O-rings, special seals, and electrical plug seals, as well as solutions for modern hybrid and electric drives. KACO offers comprehensive development expertise, from prototype production to series manufacturing, focusing on the highest precision, quality, and reliability. Thanks to state-of-the-art manufacturing processes, global production sites, and continuous innovation, KACO is a preferred partner for demanding sealing applications worldwide.

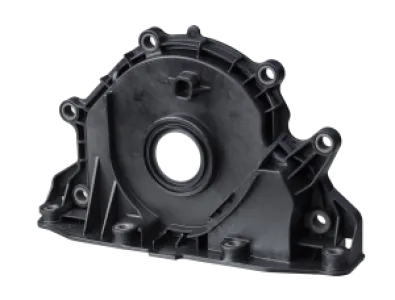

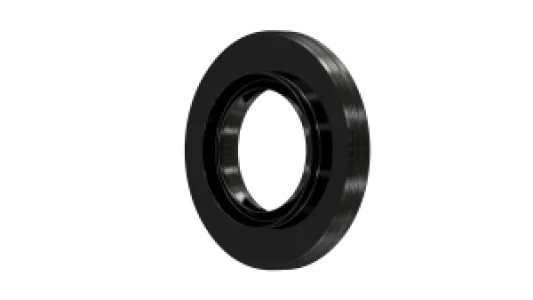

Radial Shaft Seals

KACO offers a broad portfolio of technologies for sealing dynamic sealing points of shafts for every customer specification. Depending on the medium to be sealed and the operating conditions, we select the most suitable solution for you from our broad technology portfolio.

Water Management

KACO offers state-of-the-art sealing technology for the cooling circuit. Whether for water pumps or electric drive machines, we have or develop the right solution for your application thanks to our materials and design expertise and our large product portfolio in mechanical seals.

Hydraulik & Piston Seals

KACO is a specialist in the development and production of actuation elements and shift pistons. Our products are used worldwide in hydraulic clutch systems or as active gearshift elements in the drive train. But actuating elements and shift pistons from KACO can also be used for pneumatic systems and applications outside the drive train.

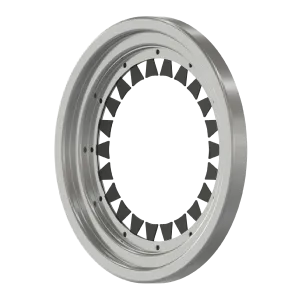

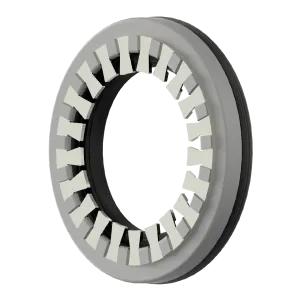

Electrical Systems & Magnetics

KACO develops and manufactures customised signal transmitters for the automotive industry and mechanical engineering. Rotating and linear applications are possible. The product group is based on two technologies. On the one hand, active elastomer-bonded ferritic signal transmitters, on the other hand, metallic shaft encoder wheels.

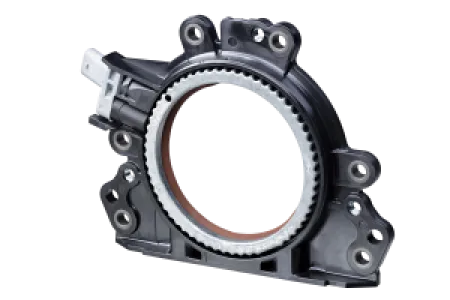

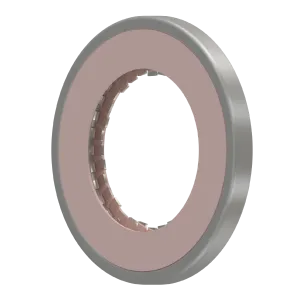

Shaft Grounding Rings

Seals & Systems for E-Mobility

KACO shaft grounding rings meet the high requirements of electric motor manufacturers. Harmful shaft voltages and bearing currents are diverted to the electrical ground to prevent bearing damage and interference noise. This is made possible by a highly conductive PTFE washer with a special coating.

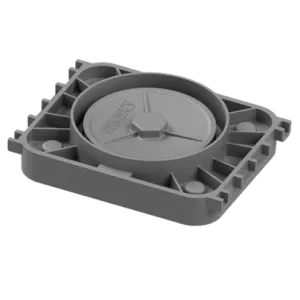

Battery Venting Systems

Quick battery venting systems from KACO ensure that the required amount of air can escape quickly in the case of a battery fault. The flow-optimized venting solutions from the sealing expert offer an excellent balance between height and maximum possible volume flow. Our emergency vents are available as reversible and irreversible solutions. All designs can be fitted with additional aeration and venting elements to ensure regular pressure equalization of the battery due to pressure and temperature fluctuations in addition to protecting against faults.

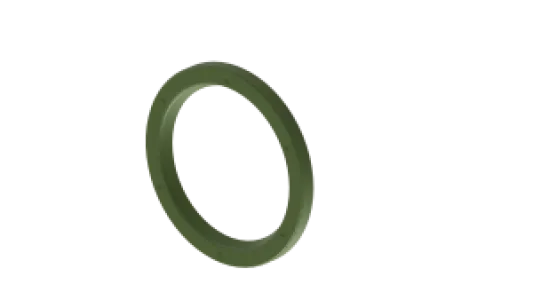

Static Seals

KACO offers a wide range of static seals. From pure moulded rubber parts to various designs bonded to carrier components, we offer the right solution for static sealing tasks. Specific requirements such as ease of assembly, functional integration or EMC protection are met according to the application.